Glass Laminating Film

Top Glass Laminating Film Manufacturer in China

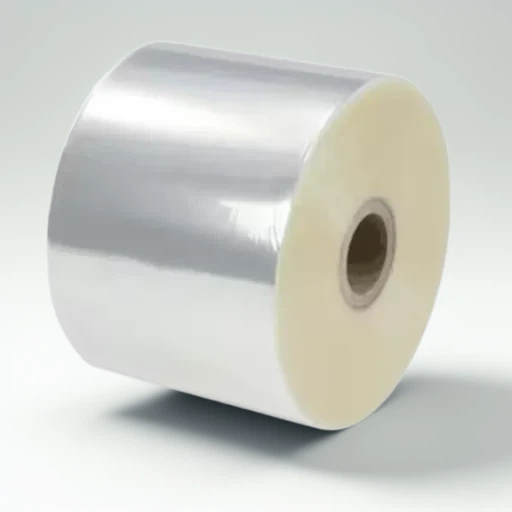

Glass laminating film would be the answer to hardening a glass surface to make it dust-resistant, durable, safe perhaps, and even aesthetically pleasing. As a highway composite film formed with the aid of cutting-edge technology, this film finds its way into applications much beyond the levels offered for residential and commercial uses, extending into automotive design and architectural design.

- Economical Pricing Options

- Rapid Solution Customization

- Worldwide Delivery

Ordering directly from the Hengning factory can save you around 30% on average.

-

Hengning's Glass Laminating Film Solution

the perfect fix for all your adhesive needs! 🔥 #adhesive #solution #innovation

When you cannot afford to compromise performance, Hengning's Glass Laminating Film comes in as the ultimate glue for your myriad needs. Our solution imparts bonding strength that surpasses others, ensuring long-term structural integrity and safety. Its formulation imparts high clarity and UV resistance, thus protecting interiors without minimizing natural light. Be it for automotive windshields, hurricane windows, or decorative partitions: Our laminating film gives a high-quality finish reputable enough to meet stringent industrial standards.

Key Benefits:

- Enhanced Safety: Holds glass fragments together upon impact, reducing the risk of injury.

- Durability: Intolerant to time of separation, moisture, and temperature variations.

- Optical Purity: Maintains original clarity and color of the glass.

- UV Protection: Blocks more than 99% of dangerous UV rays.

Specification Of Hengning Glass Laminating Film

| Material | Type | Width (mm) | Thickness (mm) | Melting Point (℃) | Press Comdition | ||

|---|---|---|---|---|---|---|---|

| Time (s) | Temp(℃) | Press(Kgf/m2) | |||||

| TPU | TB115 | 15-1650 | 0.015-0.5 | 115 | 10-30 | 130-135 | 1. 5-3.0 |

| TBK115 | 15-1650 | 0.03-0.5 | 115 | 10-30 | 130-135 | 1. 5-3.0 | |

| TB95 | 15-1650 | 0.05-0.5 | 95 | 10-30 | 110-115 | 1. 5-3.0 | |

| TB65 | 15-1650 | 0.015-0.5 | 65 | 10-30 | 80-85 | 1. 5-3.0 | |

| TBE65 | 15-1650 | 0.015-0.5 | 65 | 10-30 | 80-85 | 1. 5-3.0 | |

| TBL65 | 15-1650 | 0.015-0.5 | 65 | 10-30 | 80-85 | 1. 5-3.0 | |

| TB130 | 15-1650 | _0. 025-0.5 | 130 | 10-30 | 145-150 | 1. 5-3.0 |

Related Products

TPU film for cosmetic bag

TPU film for cosmetic bag Top TPU film for cosmetic...

Read MoreTpu Film Medical

TPU Film Medical Top TPU Film Medical Manufacturer in China...

Read MoreTPU functional film

TPU functional film Top TPU functional film Manufacturer in China...

Read MoreWaterproof Breathable Film

Waterproof Breathable Film Top Waterproof Breathable Film Manufacturer in China...

Read More

-

Why Choose Hengning's Glass Laminating Film

Explore top reasons to choose this innovative product

1. Technical Expertise

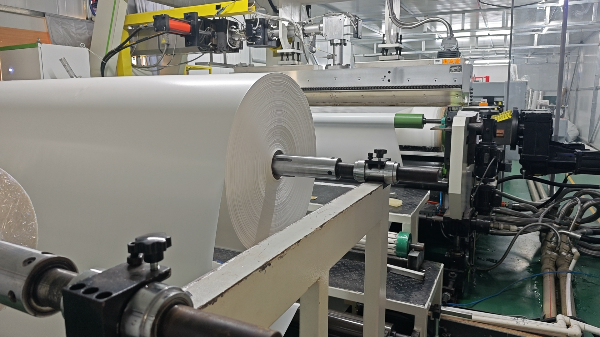

Our teams hold such a deep knowledge of polymer science and glass lamination processes that products can be applied to meet very specific technical requirements.

2. Uncompromising Quality

Stringent quality control measures are in place at every stage of the production cycle to ensure consistency from batch to batch and top reliability for the product.

3. Customizable Solutions

Various thicknesses, widths, and formulations are offered depending on the requirements of the application.

4. Global Footprint

A very strong logistics network guarantees delivery to clients all over the world within time limits.

5. Comprehensive Support

Technical support offers assistance in product selection, optimization of processing, and troubleshooting.

Welcome to Our Glass Laminating Film Factory

Latest Blog Posts

Related Topics About Glass Laminating Film

Frequently Asked Questions

Want to know more about Glass Laminating Film

Q: Explanation of glass laminating film and how it works.

A: The glass laminating film is a special interlayer film used in lamination to bind two or more layers of glass. This film increases the impact resistance of the glass window and protects it from shattering. The film usually contains EVA (ethylene vinyl acetate) that sets the layers of glass together with high optical clarity.

Q: What are the benefits of laminated glass?

A: The laminated glass brings in a lot of benefits in terms of safety and security, as it holds together even if it shatters. It insulates against sound, protects from UV rays, and is available in decorative window films for aesthetic benefits. It can also improve thermal performance and cut across all types of glazing applications.

Q: How is the lamination process carried out?

A: Laminating involves cementing a film interlayer, usually considered to be EVA or PVB, between two glass layers and subjecting the combination to heat and pressure in the autoclave, thereby causing it to bond to the glass firmly so that impact and safety are provided through a strong, durable glass-laminated panel.

Q: What are the different types of interlayer films for glass laminating?

A: There are many types of interlayer films used in glass laminating; these include EVA film for laminated glass, PVB interlayer films, and thermoplastic polyurethane films. Each type provides its own set of qualities, like safety, UV protection, or decorative options, to cover a variety of uses in the glass industry.

Q: Can these glass laminating films provide privacy?

A: Yes, glass laminating film can be used for privacy as a privacy film or in conjunction with switchable glass technologies. Films may be applied to an otherwise clear glass to provide an opaque or frosted finish, thus preventing visibility while allowing for the passage of daylight. Smart films can be switched from a transparent state to an opaque state and vice versa for added functionality.

Q: What is smart glass, and what is its relation to glass laminating?

A: Smart glass or switchable glass can change its level of opacity or transparency owing to the technology it integrates. Mostly, this is achieved with the help of applying a smart film or lamination with PDLc (polymer-dispersed liquid crystal) film. Laminating the smart films with glass gave birth to the newest privacy and light-control solution for architectural purposes.

Q: How much stronger is laminated glass than ordinary glass?

A: By preparing an interlayer film between two sheets of glass, one could produce a laminated glass. This film can be TPN, polyvinyl butyral, laminate, or any other suitable plastomer. Laminate glass, hence, is more impact-resistant and basically does not allow shattering. This is the safest glass used in the construction and automotive industries.

Q: Where are glass laminating films commonly used?

A: Glass laminating film, hence, is widely used in automotive window films, architectural panels, building safety glass, and decorative installations. It is also used in laminated glass that requires noise reduction and UV protection, rendering this product a versatile entity.

Q: How do I find the proper laminate film for my assignment?

A: The process of selecting the right laminate film for your project involves considering safety and security requirements, impact resistance, UV protection, and even aesthetic requirements. You should also consult glass manufacturers or professionals to confirm whether the film is compatible with your glass types and applications.